Streamlining Design Processes

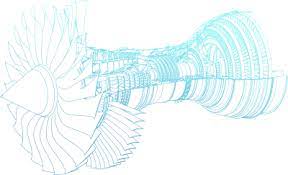

Physna’s AI-powered 3D series is a game-changer when it comes to streamlining design processes. Traditionally, designers would spend countless hours manually creating and modifying 3D models. However, with the power of AI, Physna’s software can automatically generate accurate 3D models based on input parameters. This not only saves time but also reduces human error, ensuring precision and consistency in the design phase.

Moreover, the software’s intelligent algorithms can analyze existing designs and suggest improvements. By comparing different iterations and identifying potential flaws or inefficiencies, manufacturers can optimize their products for better performance and cost-effectiveness. This level of automation and optimization has the potential to revolutionize the way products are designed, allowing manufacturers to bring innovative ideas to life faster than ever before.Enhancing Collaboration and

Communication

Collaboration and communication are vital in any manufacturing process. Physna’s AI-powered 3D series facilitates seamless collaboration between designers, engineers, and other stakeholders. The software provides a centralized platform where multiple users can work simultaneously on a 3D model, making real-time changes and sharing feedback. This eliminates the need for back-and-forth communication through emails or meetings, saving valuable time and reducing miscommunication.

Additionally, the software’s intuitive interface allows non-technical stakeholders to visualize and interact with 3D models easily. This bridges the gap between design teams and other departments, such as marketing or sales, enabling them to provide valuable input and make informed decisions. By fostering effective collaboration and communication, Physna’s AI-powered 3D series ensures that everyone involved in the manufacturing process is on the same page, leading to improved efficiency and better end products.

Optimizing Supply Chain Management

Efficient supply chain management is crucial for manufacturers to meet customer demands and stay competitive. Physna’s AI-powered 3D series offers advanced capabilities to optimize supply chain processes. By creating digital twins of physical products, manufacturers can simulate and analyze various scenarios, such as production capacity, transportation logistics, and inventory management.

The software’s AI algorithms can identify potential bottlenecks or inefficiencies in the supply chain and provide actionable insights for improvement. For example, it can suggest alternative suppliers or optimize production schedules to minimize costs and maximize efficiency. This level of optimization not only reduces lead times but also minimizes waste and enhances sustainability in the manufacturing process.

Ensuring Intellectual Property Protection

Intellectual property (IP) protection is a major concern for manufacturers, especially when sharing 3D models with external partners or suppliers. Physna’s AI-powered 3D series addresses this concern by providing robust security features. The software uses advanced encryption techniques to safeguard sensitive data, ensuring that only authorized individuals have access to the 3D models.

Furthermore, the software’s AI algorithms can detect similarities between different 3D models, allowing manufacturers to identify potential IP infringements. This proactive approach to IP protection helps manufacturers safeguard their designs and innovations, preventing unauthorized replication or misuse.

Conclusion:

Physna’s AI-powered 3D series, SequoiaWiggersVentureBeat, is revolutionizing the future of manufacturing. By streamlining design processes, enhancing collaboration and communication, optimizing supply chain management, and ensuring intellectual property protection, this software is empowering manufacturers to innovate, optimize, and deliver high-quality products efficiently. As AI continues to evolve, we can expect Physna’s AI-powered 3D series to play an increasingly significant role in shaping the future of manufacturing.