1. Streamlined Design Process

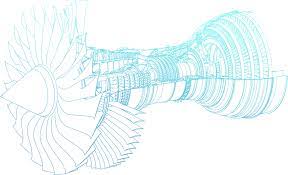

The Physna AI-Powered 3D Series offers designers a streamlined process for creating intricate 3D models. By leveraging AI algorithms, the software can automatically generate 3D models based on 2D sketches or even verbal descriptions. This eliminates the need for designers to spend countless hours manually translating their ideas into digital models. The software’s intelligent algorithms analyze the input data and generate accurate 3D models, significantly reducing design time and improving overall productivity.

Furthermore, Physna AI-Powered 3D Series provides designers with a vast library of pre-existing 3D models that can be easily modified and customized to suit their specific needs. This extensive database not only saves time but also encourages collaboration and knowledge sharing among designers. With just a few clicks, designers can access a wide range of models, accelerating the design process and fostering creativity.

2. Advanced Analysis and Optimization

One of the key features of Physna AI-Powered 3D Series is its ability to perform advanced analysis and optimization on 3D models. The software utilizes AI algorithms to identify potential design flaws, structural weaknesses, and areas for improvement. By simulating real-world scenarios and conducting virtual tests, designers can identify and rectify any issues before the product goes into production.

Moreover, Physna AI-Powered 3D Series enables designers to optimize their designs for various factors such as weight, material usage, and manufacturing costs. The software analyzes the 3D model and suggests modifications that can enhance the product’s performance while reducing its overall cost. This level of optimization not only improves the quality of the final product but also helps manufacturers save time and resources.

3. Enhanced Collaboration and Communication

Collaboration plays a crucial role in the design and manufacturing process. Physna AI-Powered 3D Series facilitates seamless collaboration among designers, engineers, and manufacturers. The software allows multiple users to work on the same project simultaneously, making it easier to exchange ideas, provide feedback, and make real-time modifications.

Furthermore, Physna AI-Powered 3D Series offers a range of communication tools that enable users to annotate, mark-up, and leave comments directly on the 3D models. This eliminates the need for lengthy email chains or face-to-face meetings, streamlining the communication process and ensuring that everyone involved is on the same page.

4. Integration with Manufacturing Processes

Physna AI-Powered 3D Series seamlessly integrates with various manufacturing processes, making it an invaluable tool for manufacturers. The software generates detailed manufacturing instructions, including specifications, tolerances, and assembly guidelines, directly from the 3D model. This eliminates the need for manual documentation and reduces the chances of errors during the manufacturing process.

Additionally, Physna AI-Powered 3D Series can generate optimized toolpaths for CNC machines, ensuring precise and efficient manufacturing. By automating these processes, manufacturers can significantly reduce production time and costs while maintaining high-quality standards.

Conclusion:

The Physna AI-Powered 3D Series represents a significant leap forward in the field of design and manufacturing. By harnessing the power of AI, this software streamlines the design process, performs advanced analysis and optimization, enhances collaboration and communication, and seamlessly integrates with manufacturing processes. With its ability to generate accurate 3D models, identify design flaws, optimize product performance, and facilitate collaboration, Physna AI-Powered 3D Series is revolutionizing the future of design and manufacturing. As AI continues to advance, we can expect even greater innovation and efficiency in this dynamic industry.